Report by RTVE: The Madrid-based company KDPOF, based in Tres Cantos, will put chips on the market in 2024. The shortage and the EU’s commitment to attract the technology industry, a business opportunity.

Spanish Company Willing to Manufacture Chips ‘Made in Spain’ in the Midst of Supply Crisis

There is a shortage of chips, that’s a fact. The causes of this supply crisis are diverse: distribution problems stemming from the pandemic, increased demand and even geostrategic issues. But experts agree that one of the most influential factors is the enormous technical complexity behind the manufacture of each chip.

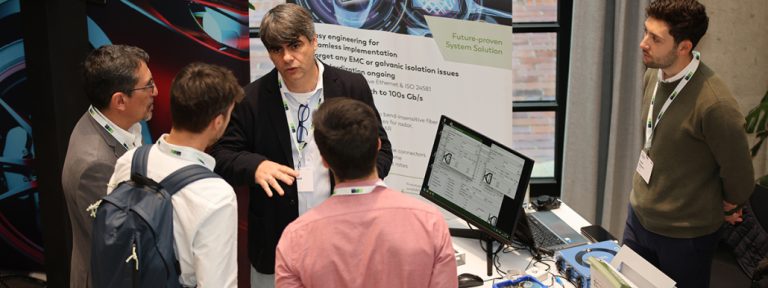

The technical director of the Spanish company KDPOF, Rubén Pérez-Aranda, explained these difficulties to Sergio Martín for Zoom Net: “It is very complicated to manufacture chips because what we have to manufacture is of a ‘ridiculous’ size”. The microelectronics industry has been adding more and more complexity in integrated circuits due to the fact that the devices that are manufactured are smaller and smaller (transistors, resistors, capacitors …) Pérez-Aranda points out that “in a standard silicon wafer”, such as those manufactured at KDPOF, “there are 10,000 chips that are going to be assembled”.

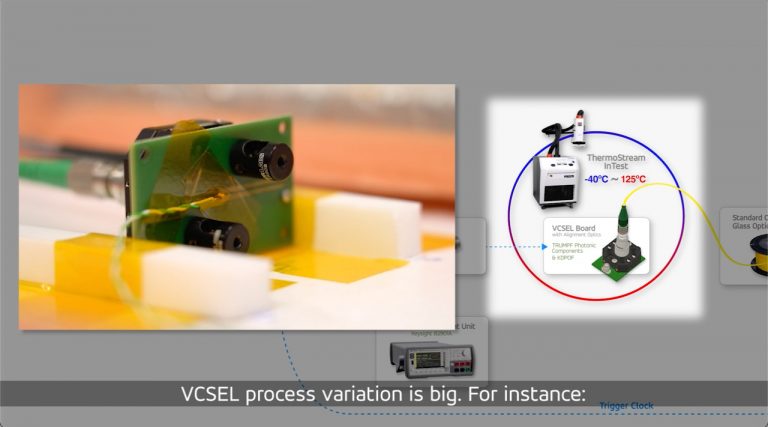

“Manufacturing a chip has three phases: creating the silicon wafer, assembling the integrated circuit and testing each chip.”

Manufacturing a chip is very complex because it takes very precise tooling for such small devices. Moreover, to simplify the process a lot, beyond the design – in which companies like KDPOF have years of experience – the development of a chip is divided into three phases: making the silicon wafer, assembling it into the integrated circuit and testing each chip. The most expensive is manufacturing the wafer.

“Setting up a fab has a huge cost; a process of about 65 nanometers costs between $1 billion and $2 billion,” estimates the technical director of the company Tricantina. “If you go to more advanced processes, for 22-28 nanometers it costs 7 billion dollars, and for five-nanometer processes the start-up of the factory costs between 16 and 18 billion dollars,” says Pérez-Aranda.

[/av_image]

In addition to the high investment required by these types of factories, it takes no less than five years to start them up, with all the accumulated experience of large manufacturers such as TSCM. The same is not true for the other two phases. Their importance in the final product accounts for two thirds of the process, but the cost of the factories for assembly and testing is measured in hundreds of millions of dollars – still a high bill – but we are no longer talking about billions, as is the case with the silicon wafer manufacturing process.

In this field, that of assembling and testing that the chip is ready to work in the device for which it has been designed, European companies in general, and Spanish companies in particular, have a lot of experience. “To set up an OSAT, which is what these types of assembly and test factories are called, a small one, can be tens of millions of dollars. That’s an opportunity to attract such factories to Europe because you have to invest less,” says KDPOF’s CTO.

“The microchip crisis, a global challenge for the consumer society”

This type of factory for assembly and testing can be ready in three years and that is where countries like Spain and companies like KDPOF can and want to be. The CEO of KDPOF, Carlos Pardo, intends to “establish in Tres Cantos some production lines for opto-electronic components for the automotive industry that will put Spain at the forefront of manufacturing”.

40 Million Euros Needed

According to the experience of the experts at KDPOF – a company that is also suffering the problems derived from the lack of supply of chips from Asia – the main bottleneck is not so much in the manufacture of silicon wafers but in the assembly and testing of the chips. For this reason, European companies with experience in this field have an opportunity. KDPOF wants to seize this opportunity. To do so, it needs at least 40 million euros. It hopes to obtain part of this investment from the EU’s IPCEI grants for “important projects of common European interest.”

“The start of the project would be in June-July next year, and within a year, the factory would have to be available here in Tres Cantos,” explains Pardo. “We would start serving carmakers during 2024.” It would be a milestone that would serve to promote the semiconductor industry in Spain. The process is technically very complex, but the shortage of semiconductors also opens the door to the manufacture of chips “Made in Spain”.